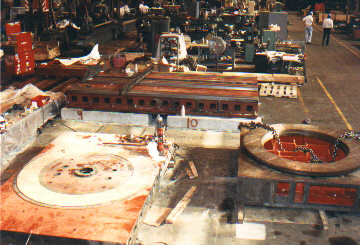

Project Summary: Precision Moglice Way Rebuild for G&L Rotary Table

This project involved the restoration and precision alignment of the bed, saddle, and table assembly for a large G&L rotary table using the Moglice injection and putty processes. Weather stripping was applied along the bed ways, and .060-inch cured Moglice shim stock was bonded to phenolic liners to prepare the bearing surfaces. Injection ports and alignment jacks were strategically installed to ensure parallelism and control gear lash.

During the process, Moglice compound was mixed, injected, and cured in place, replicating perfectly matched bearing surfaces between the saddle and bed. The result was a uniform, high-precision sliding interface requiring only minimal stoning and oil grooving. The saddle-to-bed fit utilized the Moglice injection method, while the table-to-saddle interface was finished using the Moglice putty process—achieving optimal alignment, load distribution, and long-term wear resistance across all contact surfaces.