How to Degas and Load Injectors and Caulk Tubes

Devitt Machinery – How To Mix Products Video Series

At Devitt Machinery, proper preparation is just as important as the product itself. In this how-to video, we show you how to degas and load two sizes of injectors and caulk tubes for consistent flow and clean injection results.

What This Video Covers

- How to load and degas a 100g injector (used for 100R kits)

- How to set up, load, and degas a caulk tube for larger kits (250g and 500g)

- Why removing air bubbles matters for injection performance

- Why Mogly FLP is a great injection product due to its fluid consistency

How to Degas and Load a 100g Injector (100R Kits)

We start with the 100g injector used for our 100R kits. The product being loaded in this example is Mogly FLP.

- Remove the plunger from the injector.

- Using a paper towel, plug the tip of the injector.

- Pour the product into the injector.

- To degas, slowly push the plunger while holding the injector diagonally.

- Keep pushing until product is coming out and no air bubbles are left.

- The paper towel will catch any product that comes out during this process.

Why Mogly FLP Works Well for Injection

Mogly FLP is a great product to use for injection because of its fluid consistency. This allows it to continue flowing into small voids, creating a strong bond to the metal surface. The video also shows what the cured product looks like on a flat surface.

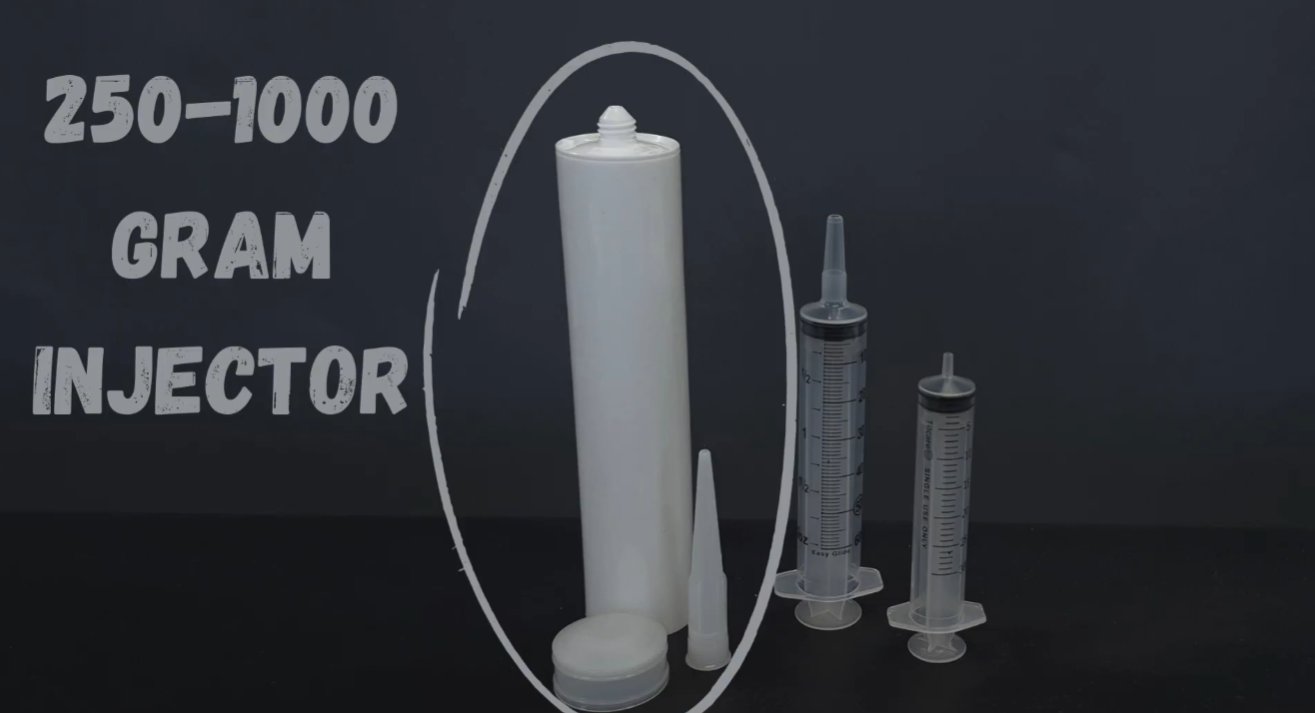

How to Set Up, Load, and Degas a Caulk Tube (250g and 500g Kits)

Next, we show how to set up and load the caulk tube using Mogly FLP for a 500g kit. This size is used for our 250g and 500g kits. For 1000g kits, you would use two of these caulk tubes.

- Cut the tip of the nozzle.

- Cut the top of the tube (do not cut below the threads).

- Screw the nozzle onto the tube.

- Using a paper towel, plug the tip of the nozzle.

- Pour the product into the tube.

- Place the plunger into the tube, dome side up.

- To degas, slowly squeeze the handle of the caulk gun while holding the tube diagonally.

- Keep squeezing until product is coming out and no air bubbles are left.

- The paper towel will catch any product that comes out during this process.

Consistent Flow Across Kit Sizes

From the 100R kit to the 500g kit, there is consistency with the product when you inject it. This flow allows you to inject into the finest of places.

What’s Coming Next

In other videos, we will show examples of the injection process on items like ball screws and acme nuts.

Need Help or Want More Videos?

All these products are available at Devitt Machinery. Give us a call or send us an email if you want to see more videos.